Acoustics insulation

Acoustics insulation

Acoustics insulation

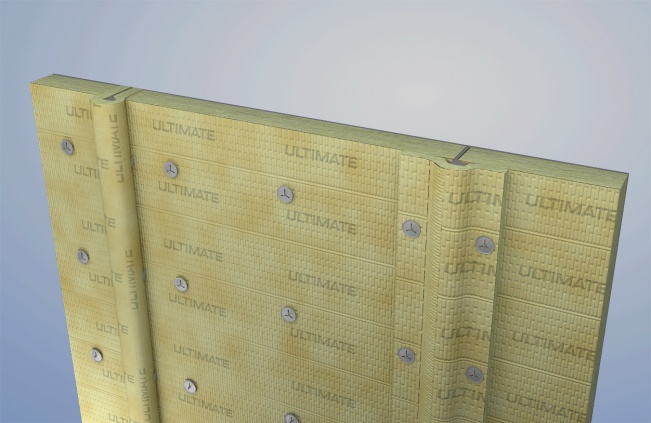

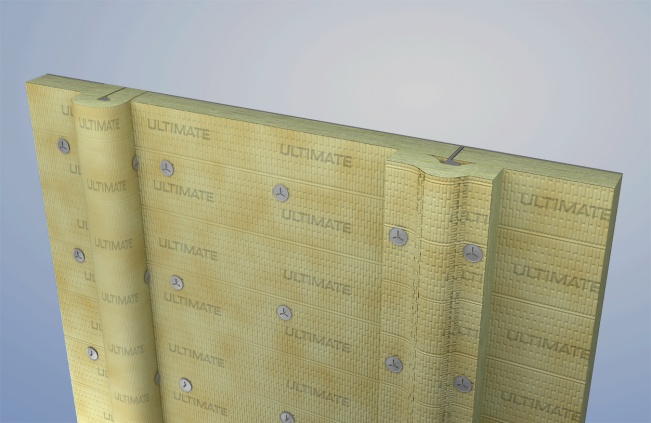

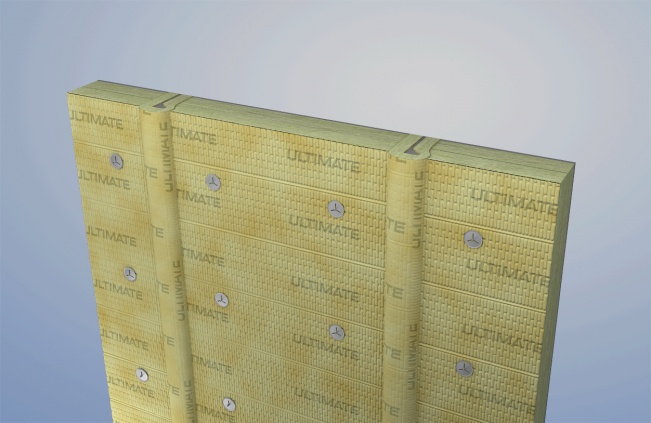

U SeaProtect Acoustic Insulation

The ISOVER range ensures improved acoustic comfort due to its excellent sound absorption and sound insulation properties.

Sound absorption in Marine Shipbuilding

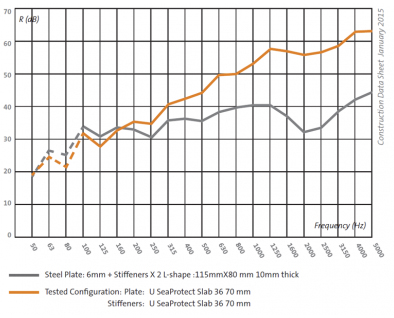

Acoustic insulation standards on board, especially in passenger ships, are continuously rising. With ISOVER ULTIMATE products whose acoustic insulation properties are improved by up to 50%, it is easy to make that decisive leap forward and provide state-of-the art acoustic solutions.

With ISOVER ULTIMATE you can achieve identical sound absorption properties at only around half the weight of traditional stone wool - saving you time and weight. And your passengers and crew? With ISOVER ULTIMATE they get improved acoustic comfort due to its high-level sound absorption properties and very good sound reduction. ULTIMATE acoustic insulation materials also have higher air-flow resistivity values, from density 24 kg/m3 onwards, compared to traditional marine stone-wool products. The product products have excellent sound absorption properties thanks to the unique internal micro-structure of the insulation mats comprising long interwoven fibers.

| Air flow resistivity (DIN EN 29053) kPa.s/m² | |

| ULTIMATE | Stone wool |

| 24 kg/m³: 15 | 50 kg/m³: 5 |

| 36 kg/m³: 30 | 70 kg/m³: 18 |

| 56 kg/m³: 50 | 100 kg/m³: 25 |

| 66 kg/m³: 60 | 120 kg/m³: 35 |

| 76 kg/m³: 80 | |

| 86 kg/m³: 90 | |

| 90 kg/m³: 100 | |

| Saint-Gobain CRIR laboratory: 19/02/2015 | |

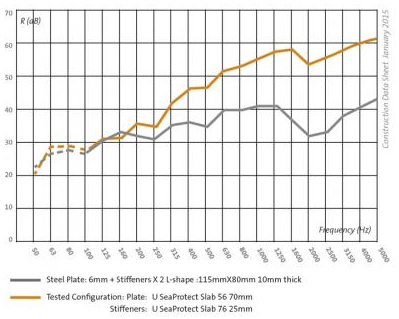

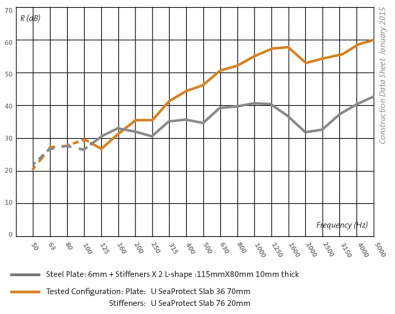

How can you achieve even better marine sound insulation results?

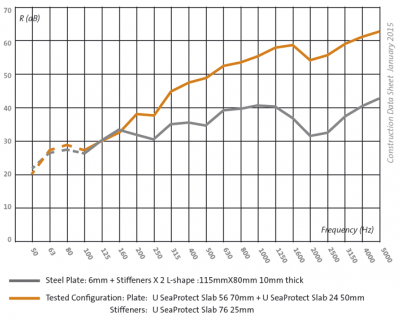

Quietude constructions are turnkey solutions for specific areas on board of your ship such as the engine/machinery rooms, discos, theatres, cinemas, designed to achieve high sound reduction performance levels (up to 53-54 dB). These constructions increase sound protection in the critical medium-low frequency range to provide technical solutions that significantly reduce noise levels.

ISOVER’s quietude sound-barrier insulation is obtained by combining SeaProtect dB-Flex Alu sound protection membrane with other U SeaProtect acoustic insulation materials. This membrane is made from a viscoelastic polymer topped with reinforced Alu facing. By applying this membrane, you can increase the sound protection of a standard SeaProtect construction to 53dB (vs. 48dB).

- Significantly enhance noise reduction, by up to 53dB

- Optimize your thermal and fire protection at the same time with ULTIMATE™ products

- Install adapted sound-dampening insulation quickly and easily