Fire Insulation

Fire Insulation

Fire Insulation

U SeaProtect Fire Solutions

The increasing focus on safety on board is leading to new constructions standards, with fire protection being key for shipbuilders and contractors.

ULTIMATE is a new generation of mineral wool: this unique range of products meets the highest standards of fire protection, including excellent levels of performance in both reaction to fire and fire resistance. ULTIMATE offers state-of-the-art fire resistance solutions for marine standard constructions. The highly streamlined product range covers all high-performance product requirements, as well as delivering logistical savings and facilitating installation on site.

With the development of U SeaProtect for Marine & Offshore applications, ISOVER offers a full line of fire protection products that comply with the 2010 Fire Test Procedures Code for fire constructions including a number of improved solutions. ISOVER’s development and sales departments teamed up to develop new solutions that would meet the highest requirements of our customers.

Lighter solutions:

New U SeaProtect solutions are increasingly lighter than traditional stone wool solutions of the previous generation. U SeaProtect solutions are up to 45% lighter than traditional stone wool solutions, providing equivalent fire certification when tested according to the FTP Code 2010.

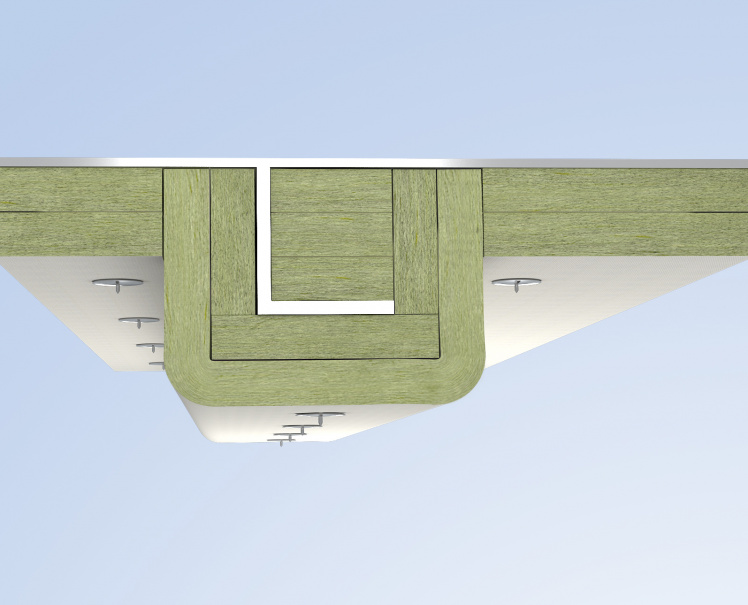

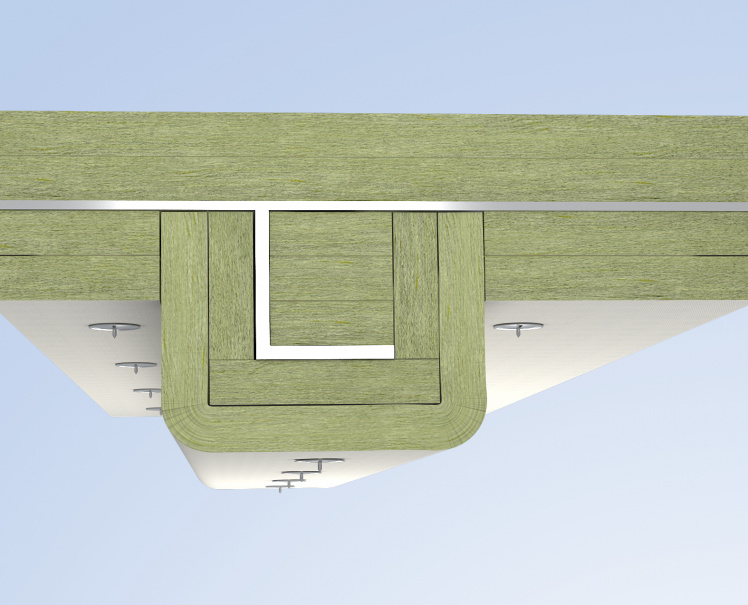

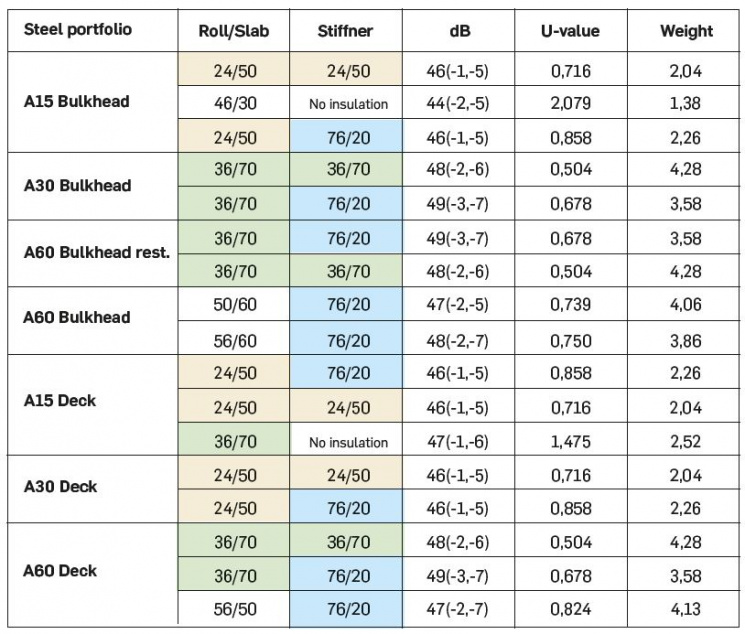

Steel Structures

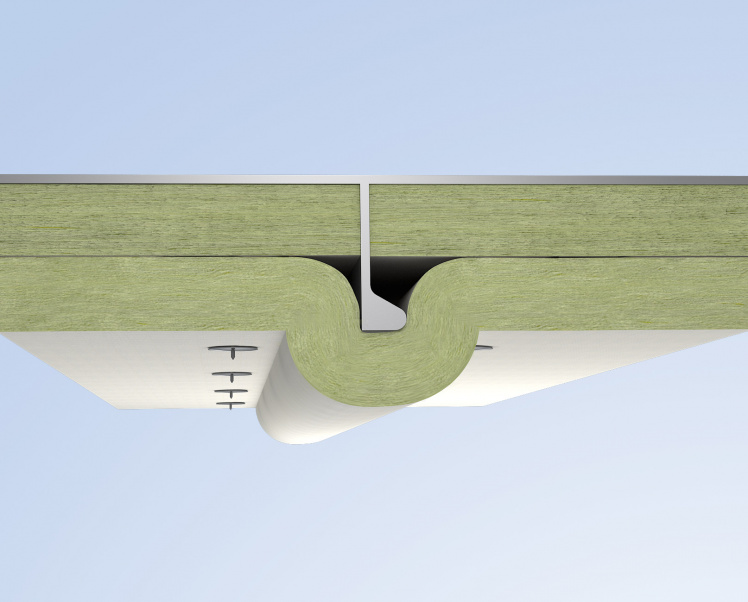

- Deck: Weight reduction of up to 60% for fire insulation of steel constructions with ULTIMATE slabs. Depending on the construction, ULTIMATE rolls may also be used for safer and more economic installation.

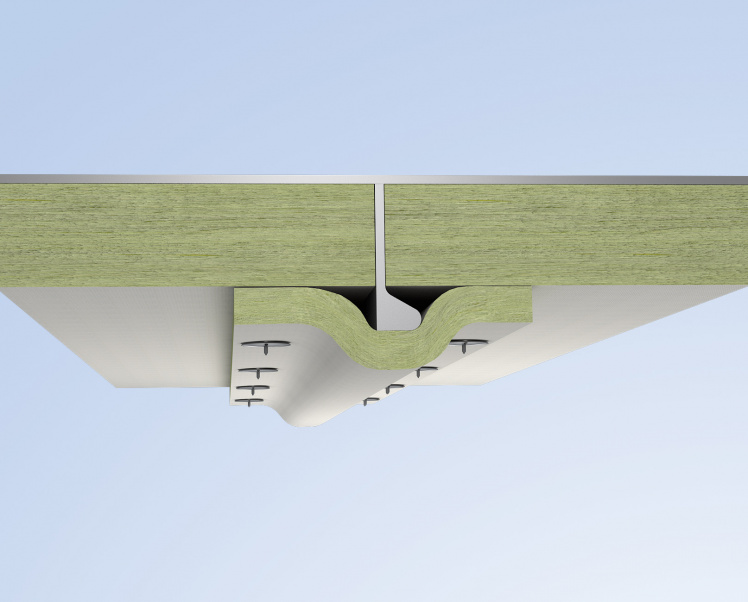

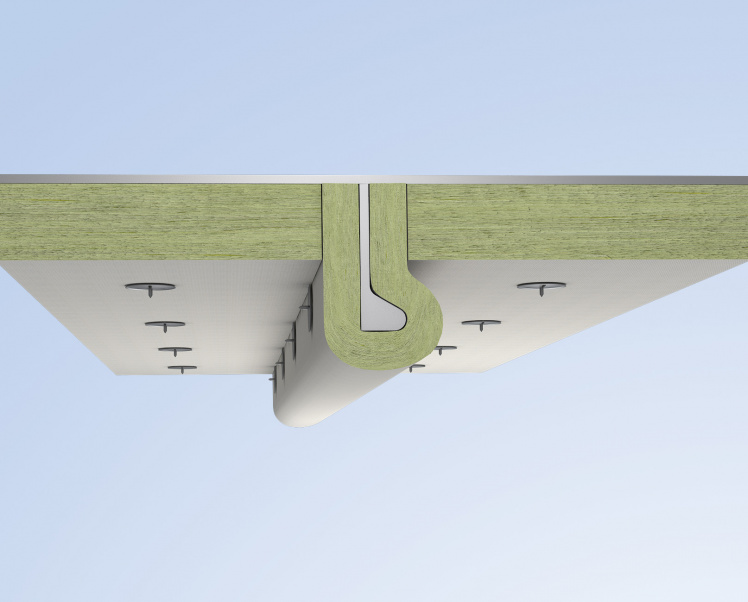

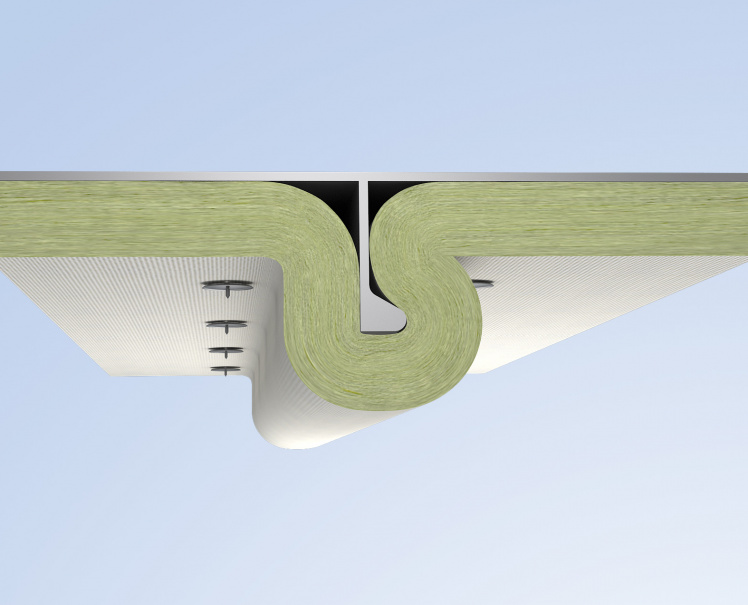

- Bulkhead: Up to 60% weight saving when insulating steel bulkhead constructions. Very fast installation as ULTIMATE product simply bends around stiffeners. ULTIMATE rolls or slabs may be used, depending on the specification.

- Floating Floor: Fire protection insulation with weight saving of up to 40%. Shorter installation time due to single-layer solutions, although double-layer solutions can be used if required. Can be finished with steel sheets or floating screeds.

Thinner solutions:

- 20 mm around the stiffeners for steel constructions (A15-A30-A60)

- 50 mm on the level for A60 steel deck

- 60 mm on the level for A60 steel bulkhead

Aluminium Structures

Light structures build in aluminium are much more expensive than steel ones. To be consistant with thos construction choice, it is must to install only lightweight solutions for fire protection of such structures.

- Deck: Weight saving of up to 35% when insulating light aluminium constructions. Very fast installation thanks to the flexibility of ULTIMATE slabs that can be simply bent around stiffeners. Highest safety: fire protection to A 60 standard.

- Bulkhead: Up to 35% weight saved with A 60 fire protection insulation. Space-saving solution as the slabs can be bent around stiffeners. Faster and more efficient installation compared to alternative solutions.

Composite/Fibre Reinforced Polymer (FRP) constructions

Light structures build in FRP sandwich panels are much more expensive than steel ones. To be consistant with thos construction choice, it is must to install only lightweight solutions for fire protection of such structures.